Crankshaft nut

Traction Owner’s Club › Forums › 6 Cylinder › General › Crankshaft nut

- This topic has 10 replies, 4 voices, and was last updated 3 years, 11 months ago by Mark Robinson.

-

AuthorPosts

-

1st May 2020 at 9:05 am #26547

Mark Robinson

ParticipantHi having trouble getting the castellated nut of the end of my crankshaft I’ve tried using a punch and it won’t budge and I’m just damaging it,

I’ve had a tool made but still can’t get it off. Any ideas?

1st May 2020 at 9:42 am #26548

1st May 2020 at 9:42 am #26548Bernie

ParticipantMark,

Those wretched nuts either work loose and cause problems or seize and cause different problems.

I suggest you drill the nut, starting with a small pilot midway between the id and od then open the hole up as much as possible without damaging the thread. That will weaken the nut enough to be able to split it with a chisel and release the stickfulness.

When we rebuilt our engines, both Phil and I fitted specially modified hex nuts with thread locking products. In addition, I made a lockplate from a modified flywheel lockplate. It ain’t pretty but it is effective (and out of sight).

If you are interested I can post some pictures of both the nut and lockplate.

B….

1st May 2020 at 9:58 am #26549Hans-Peter Dürr-Auster

Participant

Mark,

I agree with Bernie, you have to destroy the nut. It might be welded on one point to the crankshaft, what I found with all my 15-6D engines. Then we prepared new nuts with standard measures for a big spanner and the security fixed as shown in picture. Don’t mind, in the photo it’s a 15-6G engine, but our procedure was identic to D-engines. This G-engine ist entirely rebuilt in CH, its brother beside. Mark Harding put the one in the picture into my 15-6G Berline 1939.

Hans1st May 2020 at 11:17 am #26554Mark Robinson

ParticipantThanks guys, Bernie will drill the nut tomorrow and take my tine not to damage the thread And yes please post your lock plate, is it like Hans?

i cant see any welding on it but i was warned of this happening i will another Aust club found he had to cut the flywheel off to remove it.

cheers

Mark

1st May 2020 at 11:26 am #26556Mark Robinson

ParticipantThis is the tool I made to try and get it off to no avail and also a pic of what another member here in Melb found “welded”

1st May 2020 at 1:57 pm #26563

1st May 2020 at 1:57 pm #26563Philippe Allison

Participant This was my solution, a new nut and thread lock and a wire.

This was my solution, a new nut and thread lock and a wire.Below is the hole cut in the bulkhead by the previous owner to access and tighten the nut that keeps coming loose. This also allowed the bulkhead to flex and rendered the handbrake useless.

Good luck Philippe

2nd May 2020 at 4:12 pm #26576

2nd May 2020 at 4:12 pm #26576Bernie

ParticipantMark,

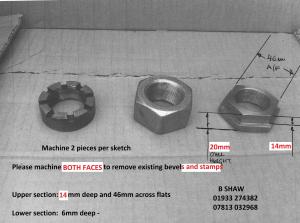

Nut and lockplate detail, as requested ……….

Modified nut :

And this is my solution for the locking plate (made from a flattened flywheel locking plate). Note it locks the six damper fixings as well as the main nut :

N.B. – To ensure the slots align correctly with 3 of the flats on the nut, they can only be cut once the central nut is fully tightened. To determine the correct slot positions, temporarily attach the plate by two or three of the six fixings then the edges of the nut can be located and marked by gently tapping the plate with a ball peen hammer.

B…………

3rd May 2020 at 7:13 am #26583Mark Robinson

ParticipantThanks everyone,

managed to get it off after more than an hour, using the careful drill and chisel method.

After doing it my nephew asked why didn’t i just weld a normal Hex nut on the back of try Castellated nut This is probably a good idea.

Mark

My bulkhead has also been cut and repaired.

3rd May 2020 at 1:20 pm #26592Philippe Allison

ParticipantThere are some hooligans ou there!!!!

3rd May 2020 at 2:09 pm #26593Bernie

ParticipantPhil

I assume you are reffering to the earlier treatment of the original nut and not my unique modification to the locking plate.

B….

4th May 2020 at 9:22 am #26594Mark Robinson

Participant A nut Gould be tack welded to the back to remove a tight nut.

A nut Gould be tack welded to the back to remove a tight nut. -

AuthorPosts

- You must be logged in to reply to this topic.